We’re thrilled to present our latest video with @Vuki a.s., showcasing how the B8650 impregnation machine and Vuki's NAB/800/Z eco-resin elevate electric motor production to new heights of sustainability and performance.

This collaboration demonstrates the effective use of Vuki’s bio-based, high-performance resin, NAB/800/Z, in the impregnation process for a cage induction motor. Engineered with high thermal resistance and anticorrosive properties, this resin maintains durability and quality while being entirely label-free and eco-friendly, with no emissions, pollution, or fire hazard risks.

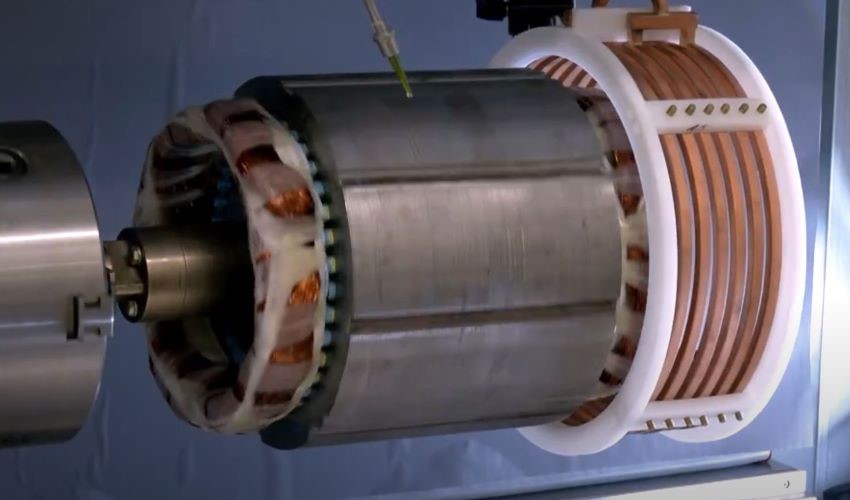

Our compact B8650 machine enables trickling and roll-dip impregnation for small-to-medium production volumes, offering the flexibility to process stators, rotors, and components up to 450mm in diameter. With semi-automated loading and unloading, it’s a space-saving solution that’s adaptable to various configurations, and capable of handling diverse impregnation needs.

Through our cutting-edge technology and sustainable materials, this process achieves:

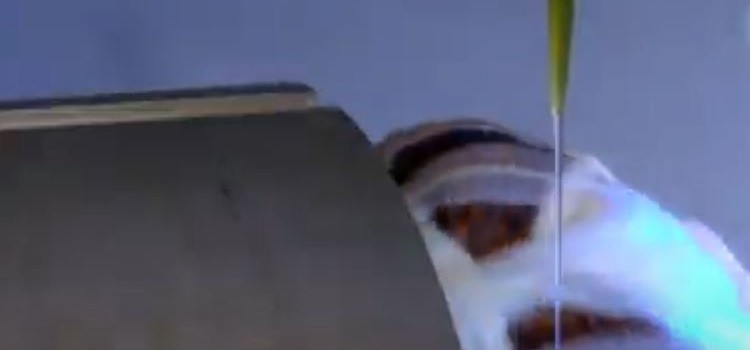

✨ Outstanding surface cleanliness post-impregnation, preserving component quality

✨ Enhanced mechanical strength and thermal resistance for long-lasting performance

✨ A highly efficient and eco-conscious process with almost no material loss

This project with Vuki represents a significant step forward in environmentally friendly manufacturing for electric motors, meeting rigorous quality standards without compromising on sustainability.

🎥 Check out our video to see how bdtronic and Vuki are transforming electric motor production with advanced, sustainable impregnation technology!

And have a look on our website for more information: https://www.bdtronic.com/en-en/impregnation-technology/

📆 Don't miss to visit our booth at the 𝗘𝗗𝗣𝗖 𝗥𝗲𝗴𝗲𝗻𝘀𝗯𝘂𝗿𝗴 from November 26-27 and talk to our experts @carlo motta and @Philippe Vandewalle about our impregnation solutions.

#SustainableManufacturing #EcoFriendlyResins #ImpregnationTechnology #bdtronic #Vuki #B8650 #ElectricMotorInnovation #Industry40

Impregnation I B8650 for small-to-medium production volumes with Vuki 1K Polyester for electric motors

In this video, bdtronic teams up with Vuki to showcase a groundbreaking approach to sustainable electric motor production. Watch as we demonstrate the power of the B8650 impregnation machine alongside Vuki's eco-friendly resin, NAB/800/Z, specifically engineered to support high-quality, high-performance electric motors.

See how Vuki’s resin, a bio-based, label-free solution with high thermal and anticorrosive properties, is applied to a cage induction motor. Our B8650 machine enables precise trickling and roll-dip impregnation, perfect for small-to-medium production needs, making it possible to achieve exceptional durability and cleanliness with no pollution, emissions, or fire hazards.

The collaboration represents a major advancement in eco-conscious manufacturing, combining bdtronic's innovative impregnation machinery with Vuki's sustainable resin technology to deliver:

• Enhanced component strength and thermal resistance

• Impeccably clean surfaces post-impregnation

• A sustainable and efficient process with minimal material loss

Explore how bdtronic and Vuki are transforming the industry with eco-friendly materials and state-of-the-art equipment. Join us in pioneering a new era of electric motor production that meets rigorous quality and environmental standards.

Get more information about bdtronic’s impregnation technology at: https://www.bdtronic.com/en-en/impregnation-technology/